Jewelry Manufacturing

by master hand

Loving Design

At the local acredo partners and on our website you will find diverse jewelry models serving as the basis for your very personal pieces of jewelry.

These models derive from the thoughts and experience of our design team.

"The design language of acredo is modern, powerful and expressive, paired with elegance and a certain naturalness."

This is the philosophy our designers follow with each of their designs. We are constantly searching for the ideal proportions and harmonious shapes.

In close cooperation with the goldsmiths, the models that you will later find in the shops are created from the best designs.

In the beginning is fire

The production of your personal pieces of jewellery begins, like the wedding ring production, with the casting of the alloy.

First, the precious metals are present in their purest form. Depending on the desired alloy, these are put together in special mixing ratios and melted at very high heat.

To achieve a first-class result, this process requires great skill and sensitivity.

In our manufactory in Pforzheim, Germany, we are specialised in producing these alloys ourselves. This distinguishes us from many other manufacturers.

Our own foundry is one of the success factors in the 80-year history of our manufactory, which is one of the leading international specialists in wedding ring and jewelry production.

From master model to favourite piece

Since earrings, pendants or necklaces are exposed to less stress than wedding rings, casting is an alternative method to wedding ring production for these pieces of jewelry.

First, the model you have chosen is cast in wax. This wax casting is placed in a flask containing an investment material. The flask is burnt out in an oven. The wax runs out due to the heating and a negative mould of the jewellery piece is created.

Now the alloy can be poured in. The success of this process requires great know-how. At the end, the investment is removed and the casting tree, on which there are usually several rings, is cleaned.

The individual ring is separated from the tree and further processed by the goldsmiths.

Stone Setting

The supreme discipline in jewelry making is the work of the jewel setters.

With great concentration and a steady hand, they place the unique diamonds in the setting you have chosen. The setters use a microscope for the precise placement of the stone and the driving of the setting.

The classic setting in jewelry is the 4- or 6-prong setting. The bezel setting, which gives the stone a closed frame, creates a very clear impression. If it is set in white precious metals, the stone appears larger.

At acredo, however, you will not only find the classic rounded prong setting. In our Cordial collection, the studs are shaped like little hearts for the romantics among you.

And if you opt for solitaire rings with an add-on setting, we achieve the hardness of wedding rings for the ring band and you have an even wider choice of settings - even with 8 prongs.

A special pleasure for our setters is the setting of large stones, often in combination with small stones in the ring shank. The moment ring shank and stone come together, the ring comes to life.

The magic of diamonds

When setting stones, each setter assumes great responsibility for the value entrusted to him.

At acredo, a wide variety of stone shapes are set: Brilliants, i.e. the round shape of diamonds, diamond hearts, the rectangular baguettes as well as the square princess diamonds.

Regardless of the stone shape, all diamonds are subjected to a thorough incoming inspection by our friendly appraisers after they arrive at the manufactory. This is how we ensure the excellent quality you can expect from us.

When you enter the stone cabinet, you not only see a sparkle in the diamonds, but also a sparkle in the eyes of the staff.

Inspiring. 100% unique. Sustainable.

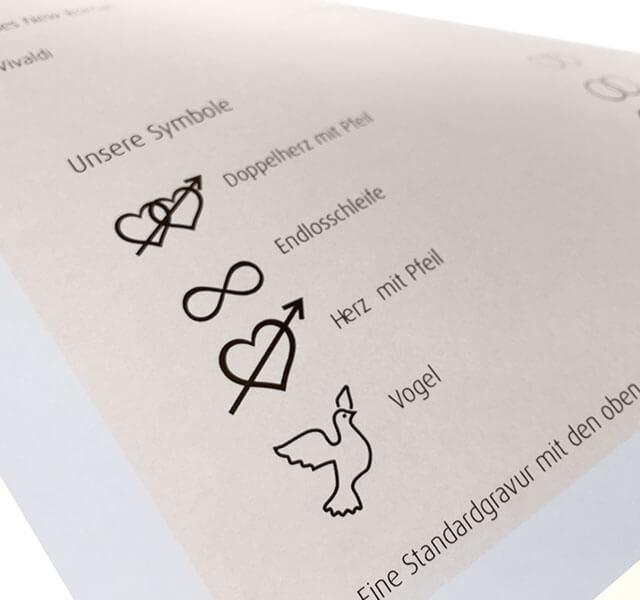

Individual Engraving

At acredo, we currently offer you a standard selection of 10 different straight as well as curved fonts for your engravings.

You provide us with a text, the date or a drawing. We then use the latest laser technology to engrave these into your rings. For this purpose, each individual ring is precisely clamped in a holder. Your data is taken over and transferred into the material by the laser.

The engraving possibilities are almost unlimited, except for reasons of space. For engagement rings, the date of meeting or engagement is suitable in combination with the name of the partner, the pet name or a saying.

Classics are: "I love you", "Je t'aime", "True Love", "Endless Love", "In love" and "Forever".

Finishes

The classic solitaire as an engagement ring is not only white gold, yellow gold or platinum. It also has a shiny polished surface.

If you want an individual design of the surface, we recommend an engagement ring that is made up of a wedding ring band and an add-on setting. Here you are free to choose between all the options. For example, you can also choose the hammered finish for a very handcrafted look.

The finishing is done in the final stage of production. In particular are called the skills of our polishers are needed here, because the process of polishing is highly sensitive and requires a very precise eye.

Quality Control

Just as each individual stone is subjected to a thorough incoming inspection by our specialists, a final quality control of the finished piece of jewelry takes place in the final phase of production.

Every detail - height, width, division, profile, surface, stone setting and engraving - is examined under the microscope.

Your piece of jewelry has passed through many qualified hands in the course of its production. With a lot of love and know-how as well as great passion, your jewelry is created in the egf manufactory in Pforzheim, Germany.